Understanding Custom Hydraulic Equipment

What is Custom Hydraulic Equipment?

Custom hydraulic equipment refers to hydraulically powered machines specifically designed and manufactured to meet unique operational requirements. These solutions typically incorporate advanced technology, customized designs, and specialized components to optimize performance in various applications. Unlike off-the-shelf hydraulic systems, custom hydraulic equipment is tailored to fit specific industry needs, providing enhanced efficiency and suitability for complex tasks.

Benefits of Customization

The primary advantage of custom hydraulic equipment lies in its ability to meet the unique needs of individual operations. This customization offers several key benefits, including:

- Increased Efficiency: Tailored solutions help optimize performance, reducing operational costs and time.

- Enhanced Capability: Custom designs can incorporate specialized features for complex or unique tasks.

- Improved Safety: Systems can be designed with safety in mind, ensuring compliance with industry regulations.

- Long-Term Reliability: Utilizing high-quality materials and tailored designs leads to reduced wear and improved longevity.

- Scalability: Custom solutions can easily adapt to changing operational requirements or technological advancements.

Common Applications in Industry

Custom hydraulic equipment finds applications across a broad spectrum of industries, including:

- Construction: Equipment such as excavators, bulldozers, and mobile cranes benefit from hydraulic systems optimized for heavy lifting and precision controls.

- Manufacturing: Hydraulic presses and automation systems are customized to enhance production efficiency and product quality.

- Aerospace: Aircraft hydraulic systems are meticulously designed for reliability and high performance under varying conditions.

- Agriculture: Specialized hydraulic solutions for tractors and harvesters improve operational efficiency in farming operations.

- Marine: Custom hydraulic systems are essential for ship control mechanisms and heavy-duty equipment onboard vessels.

Design Considerations for Custom Hydraulic Equipment

Material Selection and Durability

When designing custom hydraulic equipment, material selection plays a crucial role. Components must withstand high pressures and corrosive environments. Common materials include:

- Steel: Offers excellent strength and durability, suitable for high-load applications.

- Aluminum: Lightweight and resistant to corrosion but may require protective coatings.

- Composite Materials: Increasingly used for their strength-to-weight ratio and resistance to corrosion.

Durability and maintenance friendliness are essential to prevent downtime and extend equipment lifespan.

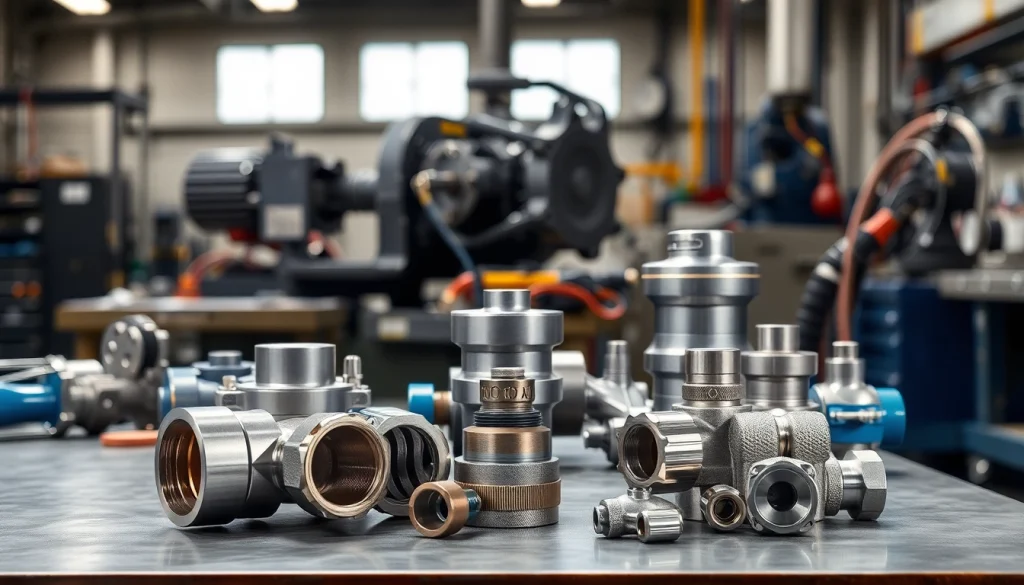

Hydraulic System Components

Custom hydraulic systems typically consist of several key components, including:

- Pumps: Responsible for converting mechanical energy into hydraulic energy.

- Valves: Control the flow and pressure of the hydraulic fluid.

- Actuators: Convert hydraulic energy back to mechanical energy to perform work.

- Reservoirs: Store hydraulic fluid, ensuring a steady supply to the system.

- Filters: Essential for maintaining fluid cleanliness and system reliability.

Each component must be selected and assembled with careful consideration for performance efficiency and compatibility.

Safety Standards and Regulations

Adherence to safety standards and regulations is paramount in the design of custom hydraulic equipment. Compliance ensures protection for operators, equipment, and the environment. Key regulations may include:

- ISO Standards: International Organization for Standardization regulations that dictate performance and safety specifications.

- OSHA Regulations: Occupational Safety and Health Administration guidelines for workplace safety.

- Local Codes: Vary by region and must be considered during the design and implementation stages.

Proactively addressing these regulations helps prevent accidents and operational disruptions.

Steps to Implement Custom Hydraulic Equipment

Assessing Your Needs

The first step in implementing custom hydraulic equipment is conducting a thorough needs assessment. This involves defining the specific tasks, environment, and operational challenges faced by your facility. Key aspects to evaluate include:

- Operational capacities and limits.

- Environmental factors that may impact equipment performance.

- Integration with existing processes and systems.

- Budget constraints.

A comprehensive understanding of these factors will form the basis for a successful custom design.

Consultation with Experts

Engaging with hydraulic system experts is a vital step in the implementation process. These professionals can provide insights based on experience and technical knowledge, assisting in:

- Design feasibility and performance expectations.

- Selection of appropriate components and materials.

- Identification of safety concerns and regulatory compliance.

This collaborative approach ensures that the custom solution aligns with operational requirements and best practices.

Prototype Development

Once the initial design and specifications have been finalized, the next step involves developing a prototype. The prototyping phase is crucial as it allows for testing and refining the design before full-scale production. This phase includes:

- Creating a scaled model or simulation of the hydraulic system.

- Conducting performance tests to identify areas for improvement.

- Incorporating feedback from the initial round of testing to optimize the system.

Prototyping significantly reduces the risk of costly modifications during the final production phase.

Maintenance of Custom Hydraulic Equipment

Regular Inspection Protocols

Maintaining custom hydraulic equipment requires establishing and adhering to regular inspection protocols. These inspections should focus on essential components and systems to ensure optimal performance. Key aspects include:

- Checking fluid levels and condition.

- Inspecting hoses and connections for leaks or wear.

- Evaluating pump and actuator functionality.

- Verifying pressure relief valves and safety features.

Regular inspections enable early detection of potential issues, minimizing unexpected downtime.

Common Maintenance Practices

Maintaining custom hydraulic equipment effectively requires the adoption of several best practices. Regular maintenance activities might include:

- Changing hydraulic fluids according to manufacturer recommendations.

- Cleaning and replacing filters to prevent contamination.

- Lubricating moving parts to reduce friction and wear.

- Calibrating gauges and control systems for accuracy.

Implementing these tasks regularly helps sustain system performance and reliability.

Extending Equipment Lifespan

To maximize the lifespan of custom hydraulic equipment, proactive measures are essential. Consider adopting the following strategies:

- Keep equipment clean and free of debris.

- Implement a documented maintenance schedule to ensure consistency.

- Continuously train operators on safe and effective equipment usage.

- Use high-quality components to minimize failure rates.

By prioritizing maintenance and proactive care, you can significantly extend the lifespan of your hydraulic systems.

FAQs about Custom Hydraulic Equipment

What is the typical lead time for custom hydraulic equipment?

Lead times vary based on complexity but generally range from a few weeks to several months, depending on specifications.

Can custom hydraulic equipment be adapted for various industries?

Yes, custom hydraulic equipment can be tailored for diverse industries like construction, manufacturing, and agriculture.

What maintenance is required for hydraulic systems?

Regular inspections, fluid changes, and checking for leaks are essential to ensure proper functionality and prevent failures.

How do I determine the right specifications for my equipment?

Assess your application needs and consult with hydraulic experts to define pressure, volume, and functionality requirements.

Are there warranty options for custom hydraulic equipment?

Most manufacturers offer warranties, covering defects and ensuring your investment is protected, with specifics varying by provider.