What is GRP Grating?

Definition and Composition of GRP Grating

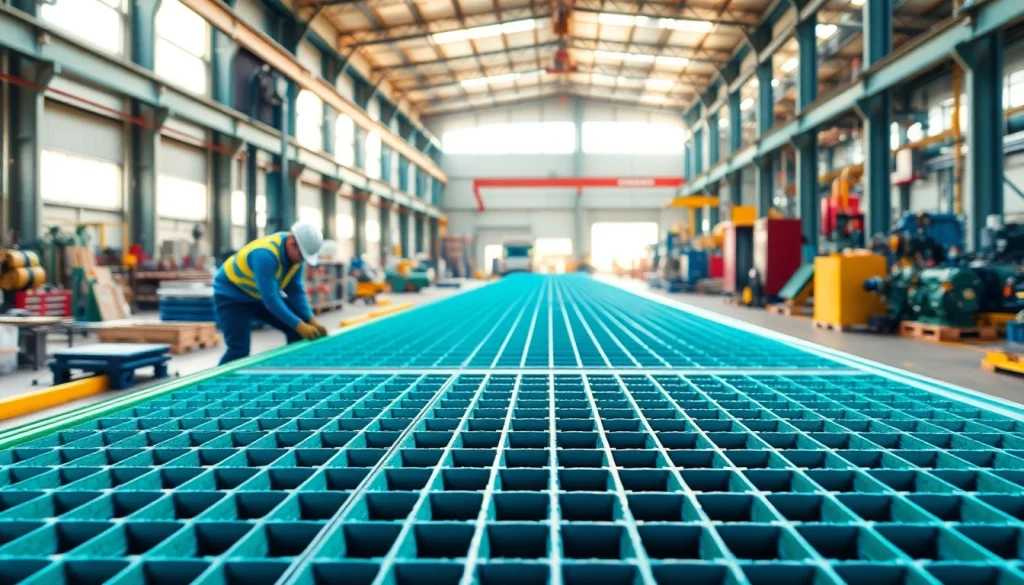

GRP (Glass Reinforced Plastic) grating is a composite material manufactured from a polymer matrix reinforced with fiberglass. This combination creates an exceptional material characterized by high strength, durability, and resistance to a range of environmental factors. It is often processed through two primary methods: molded grating, which involves forming the material into molds, and pultruded grating, which involves pulling the composite through a die to create uniform shapes.

Key Characteristics of GRP Grating Materials

- Lightweight: GRP grating is significantly lighter than traditional metal grating, making it easier to handle and install.

- Corrosion Resistance: Its resistance to corrosive environments makes GRP grating suitable for use in chemical processing and marine applications.

- Non-Slip Surface: Many GRP gratings come with textured surfaces that provide excellent traction, enhancing safety.

- Low Maintenance: GRP materials require minimal maintenance, which lowers long-term service costs.

- UV Resistant: GRP grating can withstand prolonged exposure to sunlight without degrading.

Advantages Over Traditional Grating Solutions

Compared to traditional metal and wood gratings, GRP grating offers several advantages. The lightweight nature of GRP reduces installation time and labor costs. Its naturally non-corrosive properties allow it to perform well in adverse conditions without the need for protective coatings, which can wear over time. Moreover, GRP grating can bear heavy loads while remaining easy to modify or customize for specific projects.

Benefits of Using GRP Grating Suppliers

Cost-Effectiveness and Longevity

Opting for a GRP grating supplier can lead to significant cost savings. While the initial expense may be higher than traditional materials, the durability and resistance to environmental stresses result in lower maintenance and replacement frequencies. This long lifespan ultimately contributes to cost-effectiveness over time.

Safety Features and Compliance Standards

Many GRP grating products comply with international safety standards, making them ideal for use in environments where safety is a priority, such as industrial and marine applications. The slip-resistant surfaces help prevent accidents, enhancing workplace safety.

Customization Options Available

GRP grating suppliers often provide a variety of customization options, including different sizes, colors, and load capacities. This flexibility allows project managers to tailor solutions to meet specific requirements, ensuring optimal performance in various applications. Custom colors can also enhance aesthetic appeal in visible installations.

Applications of GRP Grating in Various Industries

Industries That Utilize GRP Grating

GRP grating is extensively used across a variety of sectors, including:

- Chemical Processing: Due to its corrosion-resistant properties, GRP grating is ideal for environments with harsh chemicals.

- Water Treatment: Its non-slip surfaces and resistance to chemical breakdown make it suitable for water and wastewater treatment facilities.

- Marine Applications: GRP’s resilience to saltwater corrosion makes it a perfect choice for docks and marine environments.

- Construction: It can be used as flooring or walkways in various construction projects, providing safety and durability.

Case Studies of Successful Implementations

One notable case involved a major chemical plant that replaced their metal grating systems with GRP alternatives. The switch led to reduced maintenance costs and enhanced safety due to the lower risk of corrosion. Another example is a large-scale municipal water treatment facility that utilized GRP grating to withstand harsh chemical exposure while maintaining safety compliance, resulting in a longer service life.

Trends and Innovations in GRP Grating Usage

As industries continue to prioritize sustainable practices, GRP grating is gaining popularity due to its recyclability. Advances in manufacturing technologies are also leading to more innovative designs, such as combinations with other materials for enhanced properties and aesthetic designs suitable for architectural applications.

Factors to Consider When Choosing a GRP Grating Supplier

Evaluating Supplier Experience and Reputation

A reliable supplier should have a proven track record in the industry. Check for client testimonials and industry recognition to ensure they deliver high-quality products consistently. Specialist knowledge can be invaluable in providing the best solutions tailored to specific applications.

Product Range and Customization Capabilities

It’s essential to choose a supplier that offers a wide range of GRP grating solutions to accommodate various applications. Inquire about customization capabilities, as having options in sizing, colors, and load ratings can be crucial for unique projects.

Service Quality and Customer Support

Assessing the level of customer service provided by the supplier is critical. Prompt responses, comprehensive product advice, and post-installation support indicate a commitment to customer satisfaction and can make a significant difference in the grating selection process.

Frequently Asked Questions

What makes GRP grating superior to metal grating?

GRP grating is lighter, non-corrosive, requires less maintenance than metal alternatives, and performs well in various environmental conditions.

How can I ensure I choose a reliable GRP grating supplier?

Look for suppliers with solid reputations, customer testimonials, diverse product ranges, and responsive customer support to meet your specific needs.

What are the common applications for GRP grating?

Common uses include chemical plants, wastewater treatment facilities, and marine environments, valued for durability and non-slip surfaces.

Can GRP grating be customized for specific projects?

Yes, GRP grating can be tailored to fit project needs regarding size, color, and load-bearing capacity, enhancing its applicability.

What maintenance does GRP grating require?

Minimal maintenance is needed, usually routine cleaning to remove debris and ensure no moisture accumulates, preserving its longevity.